Reducing potable water use with greywater reuse in standalone handwashing stations

Reusing the greywater that is created after activities like doing dishes or washing laundry is one important step toward decreasing potable, or drinkable, water demand. With support from the Gates Foundation, ASU researchers have been working on a variety of innovative approaches to greywater reuse.

“Greywater accounts for 30 to 40 percent of the water use in a home,” says Paul Westerhoff, Regents’ Professor in the School of Sustainable Engineering and the Built Environment and director of the Global Center for Water Technology, a pillar of the Arizona Water Innovation Initiative. “If we can reuse that for toilet flushing, we can significantly reduce net in-home potable water demand.”

Taking this idea outside the home, Zachary Bogart, a graduate student researcher working with Westerhoff, is refining a process to treat greywater in portable, standalone handwashing stations.

“Globally, handwashing stations are a major water use and health and sanitation issue,” says Westerhoff. “This is true not just in developing economies, but also in major cities where the need is starting to be addressed with new types of sanitation systems.”

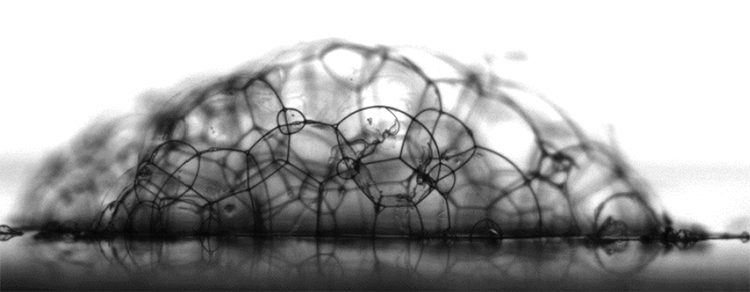

The process Bogart is researching to treat greywater is called foam fractionation. It involves creating foam by forcing air through greywater. The foam traps contaminants like soap and other particles. The foam is then removed, and the remaining water can be treated and stored for reuse

Bogart began working on water issues in high school, when he was required to participate in his Pennsylvania county science fair for his honors program. Bogart’s father showed him an article about a proposed drought solution in California, which was to cover reservoirs with what are known as shade balls to reduce evaporation.

“Shade balls are often used at airports to cover nearby ponds so there's less reflection that can impair pilot vision,” says Bogart. “But when I read this article, I thought it was strange that the shade balls were black, which would absorb a lot of heat. So I made my own shade balls in black, white and chrome to see which ones would prevent the most evaporation. I believe it was the white ones.”

Bogart is now working on this handwashing station project for his master’s thesis, and hopes to go on to pursue a doctorate with Westerhoff.

“This project is part of a larger collaboration between a couple different colleges and groups,” says Bogart. “Most of the other researchers are working with urine and nutrient recovery.”

This research is building upon work by Shahnawaz Sinha and Jirapat Ananpattarachai, both research faculty with the School of Sustainable Engineering and the Built Environment at ASU, who did the initial testing and came to the conclusion that foam fractionation was the best treatment method for achieving both water quality and energy consumption goals.

Bogart is refining their method using different approaches to forcing air into water to improve water recovery and water quality. But first he has to create the greywater.

“Right now we're making synthetic greywater with common surfactants in things like body wash and shampoo,” Bogart says. “As I force air through the water to foam it up, I’m taking advantage of the soap that was there from the handwashing to trap a lot of contaminants in the foam.”

Bogart then measures the quality of the water using a metric called chemical oxygen demand or COD, which is a measure of how much oxygen is needed to oxidize the water contaminants. He has found that he can remove 90% of COD with foam fractionation, and the more foam created, the better the water recovery.

“When it comes to using real greywater, we will have to deal with biological contaminants, and will need to add some sort of disinfection,” says Bogart. “We want to use UV light, so it's even more important for the foam to remove a lot of that particulate matter because the murkier the water is, the less effective UV.”

To do this work, Bogart spends a lot of time in the lab.

“I'm doing things like testing different bubble sizes for aeration because I've found that bubble size has a huge impact on water recovery,” says Bogart. “What I've found so far is that the larger the bubble, the more water recovery, but larger bubbles do not do as good of a job removing COD.”

The foam then has to be disposed of. Bogart says that while there are some plans to disinfect the foam by adding a salt to it and turning it back into a soap, that will take more research.

“My main goal at this point is to improve sanitation access in areas where that might be difficult due to water scarcity,” says Bogart. “There is also a big commercial prospect for it. It would be useful in tons of applications, like at concerts or on mass transit. Most water reuse systems are home scale, so it’s been interesting to work on something at this smaller scale.”

Regardless of the scale, greywater treatment and reuse is undoubtedly becoming more mainstream.

“The concept for reusing the greywater in these handwashing stations is the same as in-home greywater treatment. Here at home, we are developing partnerships with the non-profit organization 50L Home and associated companies and cities. Phoenix Mayor Kate Gallego is a global 50L Home champion,” says Westerhoff. “We have a real opportunity to create new business opportunities while also addressing water and sanitation challenges with these innovative approaches to greywater reuse.”

This Gates Foundation project is a collaboration between ASU and Rice University, and among the faculty groups of professors Westerhoff and Garcia-Segura in the ASU School of Sustainable Engineering and the Built Environment.